Art Fiber Systems (AFS) is Heading to PAT Connect 2026

We are happy to announce that Art Fiber Systems (AFS) will be exhibiting at PAT Connect 2026 in Badenweiler. As an independent system integrator, AFS

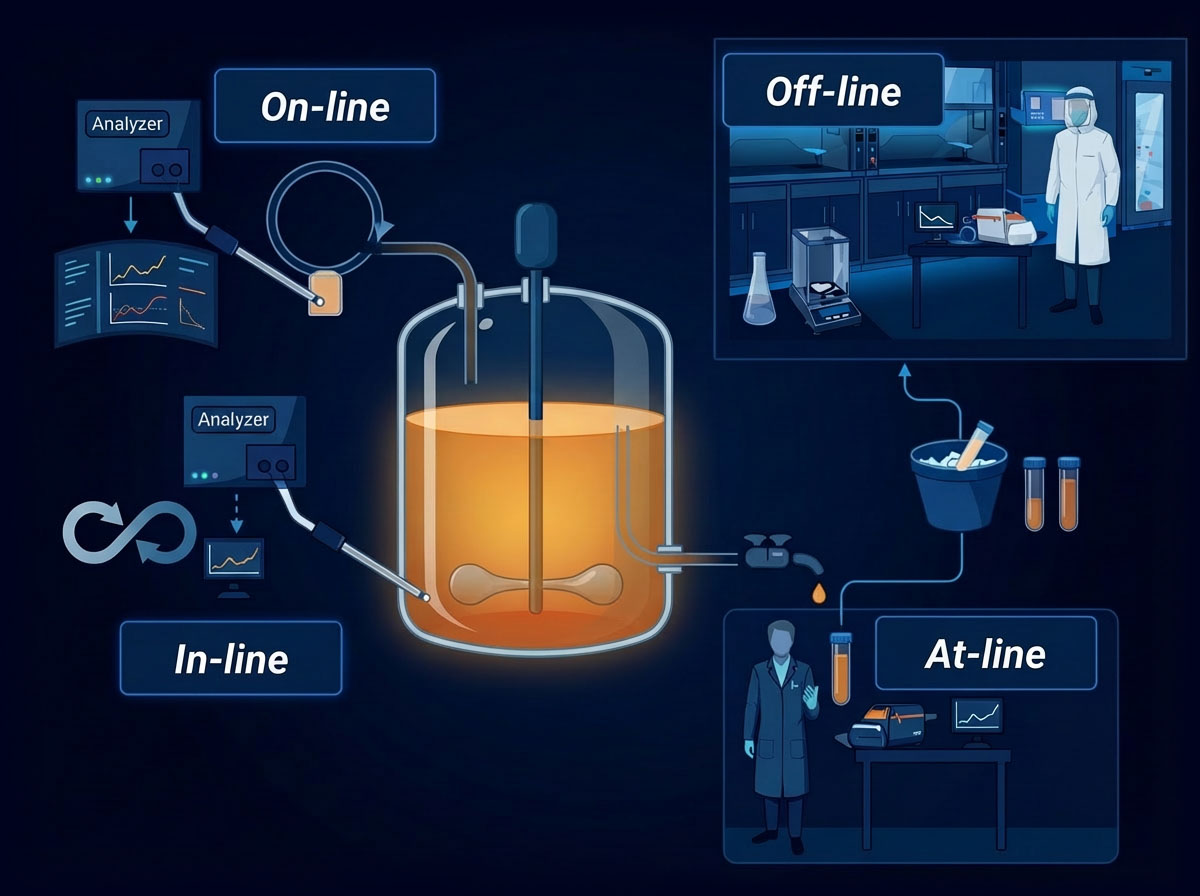

In-line spectroscopy transforms

process control from reactive

to predictive.

By measuring directly within the stream,

you eliminate sampling errors, contamination risks, and time loss.

Every second of your production becomes measurable – enabling real optimization, not assumptions.

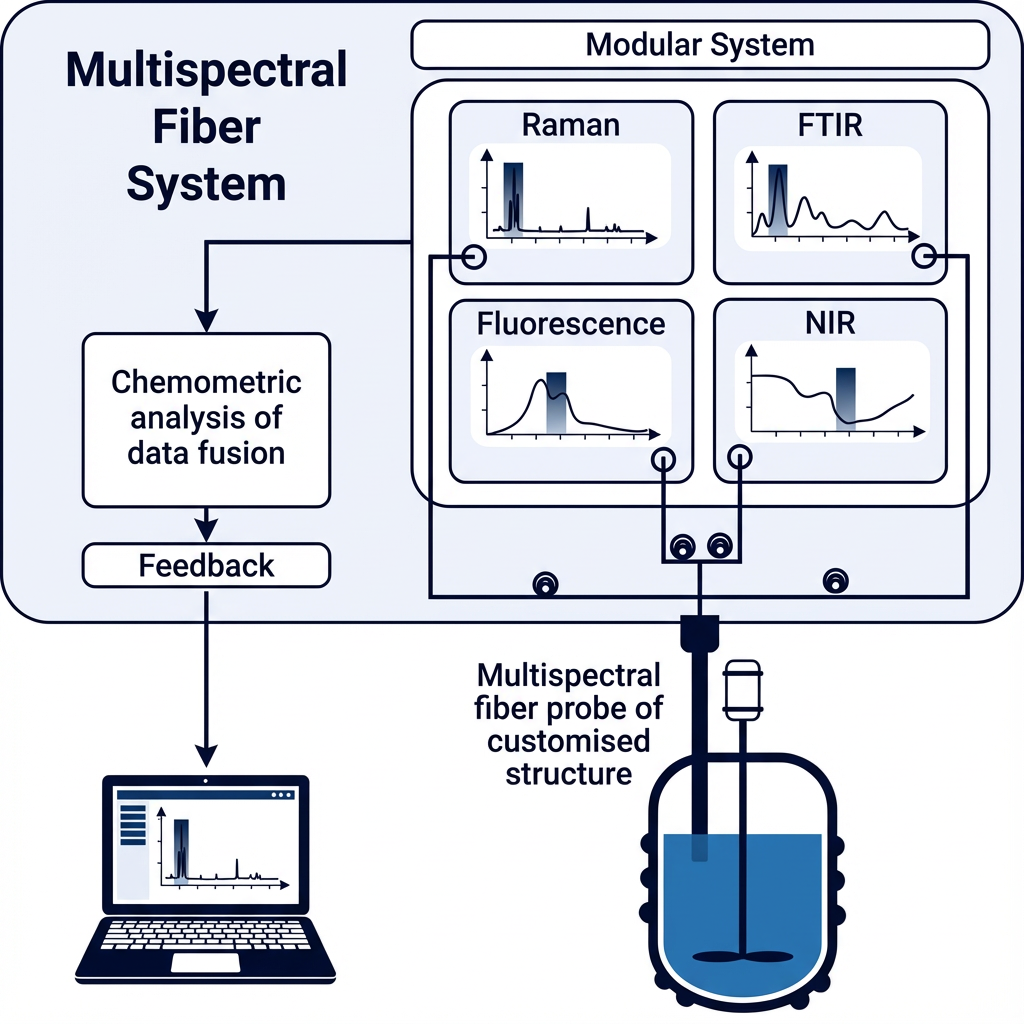

Custom-built fiber systems and sensor combinations engineered for your process.

Optional cloud-based AI processing unifies multi-spectral data and delivers continuous, real-time insights.

Durable fiber probes provide in-situ access to liquids, gases, and solids, ensuring reliable performance under high-temperature, high-pressure, or corrosive conditions.

AFS develops and tests fiber-optic spectroscopy systems that help companies find the most effective in-line method to monitor and optimize their production processes.

Inline spectroscopy delivers real-time data directly from within the process, eliminating sampling errors and delays – resulting in faster adjustments and better process efficiency.

It’s an integrated setup that combines several spectroscopy methods — ATR-absorption, Raman, Fluorescence, and UV-Vis-NIR reflection/transmission – in one platform. This allows direct comparison and selection of the most effective technique for a given process.

Our systems operate across the 0.3 – 16 µm spectral range, covering UV-Vis, Near-IR, and Mid-IR — all accessible through robust fiber-optic probes.

Any chemical, biochemical, or industrial reaction can be analyzed – including harsh, high-temperature, high-pressure, or corrosive environments. The fiber probes are designed to withstand vibration, pH extremes, and aggressive media.

We are happy to announce that Art Fiber Systems (AFS) will be exhibiting at PAT Connect 2026 in Badenweiler. As an independent system integrator, AFS

Art Fiber Systems (AFS) has successfully concluded its participation in the Asia Photonics Expo (APE 2026), held from February 4th to 6th at the Sands

Welcome to AFS Booth B503 at Asia Photonics Expo 2026 in Singapore on 4-6.02.2026 Art Fiber Systems welcomes to visit Booth B503 at Asia Photonics